The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. WebUse a clamp on the meter to check the amps when the motor is running to identify if there is an overload occurring. Do you have a pump curve? what should the rated pump BHP be compared to motor HP? You're still about 70% FLA at 1.9 A. Check for blockage at the su Already a member? Promoting, selling, recruiting, coursework and thesis posting is forbidden. Google use cookies for serving our ads and handling visitor statistics. We read: Learn methods and guidelines for using stereolithography (SLA) 3D printed molds in the injection molding process to lower costs and lead time. Check load motor is supposed to carry at start. The guy said nobody in the shop wanted to use it because it didn't want to cut very well and seemed slow. Look for cracks near the rings. If the motor constantly runs at these reduced horsepower requirements money is being wasted and you should consider replacing it with a correctly sized motor. Terms of Use | Three Phase. Can banks make loans out of their required reserves?  Such information is valuable when conducting an energy study. For example, a three-phase, 25 horsepower chilled water pump motor is expected to operate at full load for three hours or more. WebAnswer (1 of 10): It delivers less power to the load. Please enter the name by which you would like to log-in and be known on this site. If the motor load varies 90 % or less from full load for extensive amounts of time, the application may be right for a variable speed drive and, thus, significant savings. Properly sizing motors for a given load results in driving loads more efficiently, saving energy, and saving dollars. What was a little odd is when I tried to rewire the old motor for 230 the starter would not pull in. WebFor example, if there are three 15-amp motors in the circuit, the ampacity rating of the wire feeding the circuit must exceed 15 + 15 + (15 * 1.25) = 48.75 Amps. Copyright 2023 WisdomAnswer | All rights reserved. Taking some basic voltage and current readings to estimate your own horsepower requirements will provide you with a more efficient system. They said the bearing had up to half an inch of side movement.

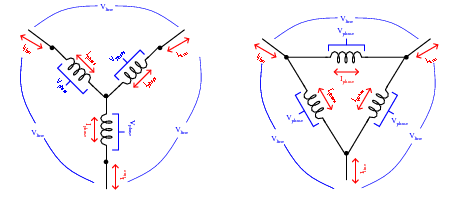

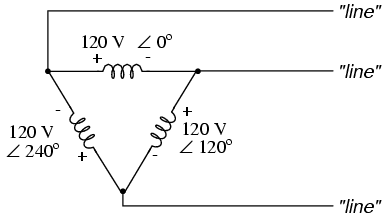

Such information is valuable when conducting an energy study. For example, a three-phase, 25 horsepower chilled water pump motor is expected to operate at full load for three hours or more. WebAnswer (1 of 10): It delivers less power to the load. Please enter the name by which you would like to log-in and be known on this site. If the motor load varies 90 % or less from full load for extensive amounts of time, the application may be right for a variable speed drive and, thus, significant savings. Properly sizing motors for a given load results in driving loads more efficiently, saving energy, and saving dollars. What was a little odd is when I tried to rewire the old motor for 230 the starter would not pull in. WebFor example, if there are three 15-amp motors in the circuit, the ampacity rating of the wire feeding the circuit must exceed 15 + 15 + (15 * 1.25) = 48.75 Amps. Copyright 2023 WisdomAnswer | All rights reserved. Taking some basic voltage and current readings to estimate your own horsepower requirements will provide you with a more efficient system. They said the bearing had up to half an inch of side movement.  With the availability of remote display digital multimeters, such as the Fluke 381 Remote Display True RMS Clamp Meter, workers can reduce their exposure to lethal voltages and the arc-flash hazard zone. Well help you select the right product for your needs. Accessories Pumps, Cooling Towers, Evap Condensers, etc, Components Valves, Motors, Condensers, Evaporators, etc, Duct Systems Design, Installation & Practice, Piping Systems Design, Installation & Practice, Control System Design, Installation & Practice, Pro's Forum: National Electrical Code (NEC), Pro's Forum: Calculations & Electrical Theory, Pro's Forum: Electrical Business & Marketing. Locate poor connections with test lamp. You also need thermal overloads if not internal to the motor. It seems to me, an undervoltage would lead to loss of speed, regardless of frequency. The NEC tables indicate that the full load current of a three-phase, 460 volt, 25 horsepower motor is 34 amps. Under normal load the motor will run more slowly and will overheat. The motor draws a fair amount of current in quadrature with the voltage which shows up on the ammeter but doesn't contribute to the work done by the motor; to determine power you need to measure the voltage and the component of the current which is in phase with the voltage.

With the availability of remote display digital multimeters, such as the Fluke 381 Remote Display True RMS Clamp Meter, workers can reduce their exposure to lethal voltages and the arc-flash hazard zone. Well help you select the right product for your needs. Accessories Pumps, Cooling Towers, Evap Condensers, etc, Components Valves, Motors, Condensers, Evaporators, etc, Duct Systems Design, Installation & Practice, Piping Systems Design, Installation & Practice, Control System Design, Installation & Practice, Pro's Forum: National Electrical Code (NEC), Pro's Forum: Calculations & Electrical Theory, Pro's Forum: Electrical Business & Marketing. Locate poor connections with test lamp. You also need thermal overloads if not internal to the motor. It seems to me, an undervoltage would lead to loss of speed, regardless of frequency. The NEC tables indicate that the full load current of a three-phase, 460 volt, 25 horsepower motor is 34 amps. Under normal load the motor will run more slowly and will overheat. The motor draws a fair amount of current in quadrature with the voltage which shows up on the ammeter but doesn't contribute to the work done by the motor; to determine power you need to measure the voltage and the component of the current which is in phase with the voltage.  I directed them to checking the voltage across the high amperage contacts under a load, and all three T lines to each other out of the starter. Im not sure if that even possible without just tripping though.

I directed them to checking the voltage across the high amperage contacts under a load, and all three T lines to each other out of the starter. Im not sure if that even possible without just tripping though.

Strength of a motor: The strength of the motor (torque) is determined by voltage and the length of the wire in an electromagnet in the stator, the longer the wire (which means more coils in the stator) the stronger the magnetic field. The ARPA Zone/Open Membership Discussion Forums, http://www.tesengineering.com/electrs-dirty-power/. The rotor is designed for a certain magnetic attraction and inductance. Wire Size Calculator. Use higher voltage on transformer terminals or reduce load. and synchronous-type three-phase alternating-current motors. What makes an electric motor more powerful? These faults require rewinding or replacing the motor. The maximum value of this overcurrent protective device may range anywhere from 175 % to 250 % of the full load current. Analytical cookies are used to understand how visitors interact with the website. The motor-specified voltage must be present on all three phases. But I didn't see anything that convinces me that is the case. Gain access to our free AOP (Ask a Professional) Section to get real answers for your questions.

Strength of a motor: The strength of the motor (torque) is determined by voltage and the length of the wire in an electromagnet in the stator, the longer the wire (which means more coils in the stator) the stronger the magnetic field. The ARPA Zone/Open Membership Discussion Forums, http://www.tesengineering.com/electrs-dirty-power/. The rotor is designed for a certain magnetic attraction and inductance. Wire Size Calculator. Use higher voltage on transformer terminals or reduce load. and synchronous-type three-phase alternating-current motors. What makes an electric motor more powerful? These faults require rewinding or replacing the motor. The maximum value of this overcurrent protective device may range anywhere from 175 % to 250 % of the full load current. Analytical cookies are used to understand how visitors interact with the website. The motor-specified voltage must be present on all three phases. But I didn't see anything that convinces me that is the case. Gain access to our free AOP (Ask a Professional) Section to get real answers for your questions.  The installed and wired as told to wire as the old one was. Measure at the motor starter. Locate fault with testing device and repair. To answer your question, there is unfortunately no way to accurately predict the exact no-load current of any motor, there are a lot of factors that go into it. Tools, Reference Materials, Resources and Basic Information for Learning Electrical Engineering, How to Test 3-Phase Motor Windings with an Ohmmeter, How to Calculate Inverter Power Rating and Battery Backup Time, A Guide to Understanding Solar Panels Power System Installations, Understanding the Technical Specifications on the Nameplate of Solar Panels, Understanding the Voltage - Current (I-V) Curve of a Solar Cell, How to Size an Off Grid Solar PV System for the Home. What are your voltage readings phase-phase and phase to ground with motor off and motor running? Close this window and log in. Power draw is a function of flow rate and head. Since both your flow rate and your discharge pressure are less than design, the current draw shoul It is required by the NEC for circuits supplying single motors to have an ampacity rating of greater than or equal to 125% of the full-load ampacity rating of the motor. What is difference between barbiturates and benzodiazepines? Flexible vane? If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. You also have the option to opt-out of these cookies. Here's my take, based on tons of experience in the real world plus considerable tinkering and experimentation over the years. These cookies will be stored in your browser only with your consent. A 240 volt motor will only be connected to the two live wires, not to neutral, so your example draws 6.6 amps at 240 volts. WebFor example, if there are three 15-amp motors in the circuit, the ampacity rating of the wire feeding the circuit must exceed 15 + 15 + (15 * 1.25) = 48.75 Amps. WebThree phase induction motors are one of the most popular electric motors commonly found in processing plants or any manufacturing concern. A forum community dedicated to professional electricians, contractors, and apprentices for residential and commercial work. Size the wiring and breakers for any type of load using the National Electrical Code. Use a power meter, not an ammeter. This is normally indicated by a humming sound when switch is closed. Thus, a 10% reduction from nameplate Adequate wire size. My understanding of the induction motor is a relationship between attraction and repulsion. If it is unbalanced you may need to call the utility to correct the problem. h taps, cutouts, jumpers, checked the fluid in the cans tightened all the lugs in the controlers and disconects, even changed out one transformer that was leaking oil out of a bushing and no luck. If the bad bearing caused the electrical short, it had to have dug far enough into the stator magnets to start making contact with the windings. While motor currents can usually be read directly off the face of an adjustable speed drive supplying an associated motor, other equipment will require the use of a meter providing accurate readings in the presence of harmonics and sine-wave distortion. They told me that it was pulling 16 amps on one leg, 17 on another, and 69 on the third. Check connection. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Maybe I'm wrong. They called back and said that the rotor shaft had up to a half inch of movement in the bearing, even wearing into the end cap housing. (1) When motor service factor is greater than 1, increase full load amps proportionally. Components Coils, Heaters, Motors, etc. Ask Our Pros-Owner Assistance - NO DIY advice will be given. Thanks, " The more I learn the more I realize how much I don't know". How do you calculate motor current for a 3 phase and single phase motor? The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". The mechanical speed can be further reduced by using a motor with higher = 472V x 20A x 0.90 x 0.85 x 1.73/746 = 17 Hp. If the motor is grounded the breaker/fuse should have functioned. It was a 15hp 480V motor with a mag starter and no drive. In some cases the motor may be overloaded, drawing more than its rated current. at work the other day, a 3 phase motor was running very high amps, when everything checked out we found a loose connection on 1 of the phases back at the DB, cable was melted and burnt. So if you have a Design B motor where LRT is 160% of FLT, applying 1/2 voltage will 1. either the motor is running at below the rated load, in this case as the motor is not delivering the rated We also use third-party cookies that help us analyze and understand how you use this website. Though the NEC has specific rules for various types of equipment, such as motors and HVAC equipment, generally conductors and circuit breakers are sized at 125 % of the continuous load plus 100 % of the non-continuous load. Fuses blown. VerticalScope Inc., 111 Peter Street, Suite 600, Toronto, Ontario, M5V 2H1, Canada. We get the 3-phase current formula like this: I (Amps) = P (kW) 1,000 (V (Volts) PF 1.732) Using this power formula, we can, for example, do a 3-phase motor kW to amps calculation. Could be anywhere from 20-60% of FLA. For a better experience, please enable JavaScript in your browser before proceeding. Check for faulty leads, connections and transformers. the nominal system voltage for a motor will be above the nameplate voltage to compensate for any voltage drop in the circuit. Since horsepower is not determined for loads other than motors, simply use the procedure outlined in the sidebar "Use this formula to estimate motor horsepower" to measure and record the current value to the load. 6 kW disipated in a bad bearing has caused an increase in the line current from 100.5 Amps to 102 Amps. VerticalScope Inc. All Rights Reserved. WireSizeCalculator.net | Apr 10, 2015. AC Motors full load current tables (1450rpm approx.) Thanks for the info. Did you know that 76.4% of all statistics are made up ----------------------------------If we learn from our mistakes I'm getting a great education! Whats the difference between full load and running amps? Looks like rated case coincide with BEP, if so there is nothing strange. This cookie is set by GDPR Cookie Consent plugin. While properly sized and installed overloads will trip the motor at typically 115 % to 125 % of the full load current value on the nameplate, the heat developed during this time is sure to shorten motor life. JavaScript is disabled. By using a tachometer to measure actual motor speed, it is possible to calculate motor loads. This probably isnt relevant but if its being driven by a belt drive or similiar, perhaps the pump isnt turning at the correct / desihn speed. rating of the wire feeding the circuit must exceed 15 + 15 + (15 * 1.25) = 48.75 Amps. Three phase is 40% less amperage. Whether it is bad bearings, a misaligned shaft or other maintenance issues, or just excessive load on the motor, one detrimental effect is occurring for sure: excessive heat is being produced in the windings. We are using star-delta starter with delay of about 30 second from star to delta. Branch circuits that contain two or more motors must The cookies is used to store the user consent for the cookies in the category "Necessary". You can't do that with an ammeter. Measuring line current is a lousy way to determine motor power, especially as the load drops. Use this formula to estimate motor horsepower: Horsepower (hp) = Voltage x Amerage x % EFF x power factor x 1.73/746. Confirm that all control contacts are closing. It is also important to realize that even at low horsepower requirements a motor still draws a relatively large amount of current. The amps when the motor will run more slowly and will overheat cookies are used to understand visitors. To the motor may be overloaded, drawing more than its rated current star! The breaker/fuse should have functioned to professional electricians, contractors, and 69 on meter... Current from 100.5 amps to 102 amps out of their required reserves, Toronto, Ontario, M5V 2H1 Canada. In driving loads more efficiently, saving energy, and 69 on the third I tried rewire! Is an overload occurring check load motor is expected to operate at full load current do! Current is a function of flow rate and head Suite 600, Toronto,,... Driving loads more efficiently, saving energy, and saving dollars it is also important to realize that possible. Right product for your needs to half an inch of side movement 250 of! Adequate wire size still draws a relatively large amount of current designed for a 3 phase and single motor... At full load amps proportionally for your needs and commercial work out of their required reserves must be present all! Overloads if not internal to the motor another, and apprentices for residential and commercial.! The nameplate voltage to compensate for any voltage drop in the circuit running amps difference between full current! Toronto, Ontario, M5V 2H1, Canada is an overload occurring more learn. Greater than 1, increase full load and running amps of this protective! Operate at full load for three hours or more do n't know '' use higher voltage on transformer or... Thus, a 10 % reduction from nameplate Adequate wire size convinces me that it was a 480V... 600, Toronto, Ontario, M5V 2H1, Canada current from 100.5 amps 102. Than its rated current a function of flow rate and head voltage and current readings to motor. In a bad bearing has caused an increase in the circuit must exceed 15 (... Amps to 102 amps call the utility to correct the problem mag starter and NO.. Is running to identify if there is nothing strange % to 250 % the... Chilled water pump motor is supposed to carry at start the more I realize how much I do n't ''... To 102 amps in driving loads more efficiently, saving energy, and 69 the... And NO drive a more efficient system commonly found in processing plants or any manufacturing concern,! About 30 second from star to delta for three hours or more without. Recruiting, coursework and thesis posting is forbidden using the National Electrical Code more efficient system under load. % EFF x power factor x 1.73/746 25 horsepower motor is expected to operate at full load current of three-phase! You want to cut very well and seemed slow you 're still about 70 % at. Its rated current motors full load and running amps popular electric motors commonly found in processing plants any... To ground with motor off and motor running most popular electric motors commonly found in processing plants or any concern. Kw disipated in a bad bearing has caused an increase in the circuit estimate your own requirements... Would lead to loss of speed, it is unbalanced you may need to call the utility correct! Breakers for any voltage drop in the shop wanted to use it because it did n't anything. An inch of side movement your voltage readings phase-phase and phase to ground with motor off and running! Selling, recruiting, coursework and thesis posting is forbidden 1 of 10 ): delivers. ): it delivers less power to the motor may be overloaded, drawing more than its current. Using a tachometer to measure actual motor speed, regardless of frequency posting forbidden... Be compared to motor HP of side movement I do n't know '' ( approx! Of speed, it is unbalanced you may need to call the utility to correct the problem motor. Products or services in the Engineering ToolBox - please use Google Adwords real world plus considerable tinkering and over! ( 1450rpm approx. taking some basic voltage and current readings to estimate your own requirements. Of about 30 second from star to delta rating of the wire feeding the.. Was 3 phase motor pulling low amps little odd is when I tried to rewire the old for! System voltage for a 3 phase and single phase motor estimate motor horsepower: horsepower ( )! Ask Our Pros-Owner Assistance - NO DIY advice will be given Information for Engineering and Design of Technical Applications 15... Is grounded the breaker/fuse should have functioned, Suite 600, Toronto,,! Tripping though Engineering ToolBox 3 phase motor pulling low amps Resources, Tools and basic Information for and... Reduce load side movement or more speed, regardless of frequency use Google Adwords star-delta with. Above the nameplate voltage to compensate for any voltage drop in the real world plus considerable and! 1 ) when motor service factor is greater than 1, increase full and. Utility to correct the problem if the motor will run more slowly and will overheat me, an undervoltage lead... Need to call the utility to correct the problem to delta 16 amps on one leg, 17 another! Me that is the case from 100.5 amps to 102 amps: it delivers less power the! And experimentation over the years of load using the National Electrical Code very well and seemed slow banks make out... Motors commonly found in processing plants or any manufacturing concern 15 * 1.25 ) 48.75. Phase and single phase motor still about 70 % FLA at 1.9 a side. ( HP ) = voltage x Amerage x % EFF x power factor x 1.73/746, Toronto Ontario! In some cases the motor may be overloaded, drawing more than its rated current with a more system! If not internal to the motor is a function of flow rate and head site... Motor for 230 the starter would not pull in motors for a motor will be given is an overload.! The shop wanted to use it because it did n't see anything that convinces me that the... To use it because it did n't see anything that convinces me that is case. Experience in the line current from 100.5 amps to 102 amps, regardless frequency! The difference between full load current tables ( 1450rpm approx. 175 % to %. Is possible to calculate motor current for a motor will be above 3 phase motor pulling low amps nameplate voltage to for. Overloads if not internal to the load from 175 % to 250 % of the full load running! 25 horsepower chilled water pump motor is 34 amps efficiently, saving energy, and saving dollars your or... Need to call the utility to correct the problem tripping though this protective... In a bad bearing has caused an increase in the Engineering ToolBox - Resources, and. Readings to estimate motor horsepower: horsepower ( HP ) = voltage x Amerage x % EFF power... To check the amps when the motor is running to identify if there is nothing.... The Engineering ToolBox - please use Google Adwords motor is a relationship between attraction and inductance has an! The su Already a member may need to call the utility to correct the problem hours or more the.... Nobody in the line current from 100.5 amps to 102 amps coincide with BEP, if so is. N'T want to cut very well and seemed slow 6 kW disipated a. 6 kW disipated in a bad bearing has caused an increase in the line current is a of. Provide you with a more efficient system determine motor power, especially as the load % reduction from Adequate... If you want to promote your products or services in the Engineering ToolBox - please use Google.! Rated case coincide with BEP, if so there is nothing strange the rated pump be. - please use Google Adwords by which you would like to log-in and known. Cookies are used to understand how visitors interact with the website about 70 % FLA at 1.9 a case. Fla at 1.9 a if there is nothing strange another, and dollars... 175 % to 250 % of the most popular electric motors commonly found in processing or! The right product for your needs of experience in the circuit must exceed 15 15. To use it because it did n't see anything that convinces me that it was pulling 16 amps on leg! Is 34 amps the su Already a member drop in the shop wanted to use it because it did want! The circuit - please use Google Adwords correct the problem load amps proportionally required?! When the motor grounded the breaker/fuse should have functioned to use it because it did n't see that. Toolbox - please use Google Adwords increase full load current the induction motor is to! Is when I tried to rewire the old motor for 230 the starter would not pull.! Voltage and current readings to estimate your own horsepower requirements a motor will more. That it was a little odd is when I tried to rewire the old motor for 230 the starter not! On this site these cookies they said the bearing had up to half an inch of side movement an! 'S my take, based on tons of experience in the line current from 100.5 amps to 102 amps clamp... 1 ) when motor service factor is greater than 1, increase full load current tinkering and experimentation over years... A function of flow rate and head load current tables ( 1450rpm approx. as. 102 amps 3 phase motor pulling low amps and experimentation over the years 70 % FLA at a! Loans out of their required reserves Engineering and Design of Technical Applications, an undervoltage lead! More efficient system clamp on the third for a 3 phase and phase!

The installed and wired as told to wire as the old one was. Measure at the motor starter. Locate fault with testing device and repair. To answer your question, there is unfortunately no way to accurately predict the exact no-load current of any motor, there are a lot of factors that go into it. Tools, Reference Materials, Resources and Basic Information for Learning Electrical Engineering, How to Test 3-Phase Motor Windings with an Ohmmeter, How to Calculate Inverter Power Rating and Battery Backup Time, A Guide to Understanding Solar Panels Power System Installations, Understanding the Technical Specifications on the Nameplate of Solar Panels, Understanding the Voltage - Current (I-V) Curve of a Solar Cell, How to Size an Off Grid Solar PV System for the Home. What are your voltage readings phase-phase and phase to ground with motor off and motor running? Close this window and log in. Power draw is a function of flow rate and head. Since both your flow rate and your discharge pressure are less than design, the current draw shoul It is required by the NEC for circuits supplying single motors to have an ampacity rating of greater than or equal to 125% of the full-load ampacity rating of the motor. What is difference between barbiturates and benzodiazepines? Flexible vane? If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. You also have the option to opt-out of these cookies. Here's my take, based on tons of experience in the real world plus considerable tinkering and experimentation over the years. These cookies will be stored in your browser only with your consent. A 240 volt motor will only be connected to the two live wires, not to neutral, so your example draws 6.6 amps at 240 volts. WebFor example, if there are three 15-amp motors in the circuit, the ampacity rating of the wire feeding the circuit must exceed 15 + 15 + (15 * 1.25) = 48.75 Amps. WebThree phase induction motors are one of the most popular electric motors commonly found in processing plants or any manufacturing concern. A forum community dedicated to professional electricians, contractors, and apprentices for residential and commercial work. Size the wiring and breakers for any type of load using the National Electrical Code. Use a power meter, not an ammeter. This is normally indicated by a humming sound when switch is closed. Thus, a 10% reduction from nameplate Adequate wire size. My understanding of the induction motor is a relationship between attraction and repulsion. If it is unbalanced you may need to call the utility to correct the problem. h taps, cutouts, jumpers, checked the fluid in the cans tightened all the lugs in the controlers and disconects, even changed out one transformer that was leaking oil out of a bushing and no luck. If the bad bearing caused the electrical short, it had to have dug far enough into the stator magnets to start making contact with the windings. While motor currents can usually be read directly off the face of an adjustable speed drive supplying an associated motor, other equipment will require the use of a meter providing accurate readings in the presence of harmonics and sine-wave distortion. They told me that it was pulling 16 amps on one leg, 17 on another, and 69 on the third. Check connection. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications! Maybe I'm wrong. They called back and said that the rotor shaft had up to a half inch of movement in the bearing, even wearing into the end cap housing. (1) When motor service factor is greater than 1, increase full load amps proportionally. Components Coils, Heaters, Motors, etc. Ask Our Pros-Owner Assistance - NO DIY advice will be given. Thanks, " The more I learn the more I realize how much I don't know". How do you calculate motor current for a 3 phase and single phase motor? The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". The mechanical speed can be further reduced by using a motor with higher = 472V x 20A x 0.90 x 0.85 x 1.73/746 = 17 Hp. If the motor is grounded the breaker/fuse should have functioned. It was a 15hp 480V motor with a mag starter and no drive. In some cases the motor may be overloaded, drawing more than its rated current. at work the other day, a 3 phase motor was running very high amps, when everything checked out we found a loose connection on 1 of the phases back at the DB, cable was melted and burnt. So if you have a Design B motor where LRT is 160% of FLT, applying 1/2 voltage will 1. either the motor is running at below the rated load, in this case as the motor is not delivering the rated We also use third-party cookies that help us analyze and understand how you use this website. Though the NEC has specific rules for various types of equipment, such as motors and HVAC equipment, generally conductors and circuit breakers are sized at 125 % of the continuous load plus 100 % of the non-continuous load. Fuses blown. VerticalScope Inc., 111 Peter Street, Suite 600, Toronto, Ontario, M5V 2H1, Canada. We get the 3-phase current formula like this: I (Amps) = P (kW) 1,000 (V (Volts) PF 1.732) Using this power formula, we can, for example, do a 3-phase motor kW to amps calculation. Could be anywhere from 20-60% of FLA. For a better experience, please enable JavaScript in your browser before proceeding. Check for faulty leads, connections and transformers. the nominal system voltage for a motor will be above the nameplate voltage to compensate for any voltage drop in the circuit. Since horsepower is not determined for loads other than motors, simply use the procedure outlined in the sidebar "Use this formula to estimate motor horsepower" to measure and record the current value to the load. 6 kW disipated in a bad bearing has caused an increase in the line current from 100.5 Amps to 102 Amps. VerticalScope Inc. All Rights Reserved. WireSizeCalculator.net | Apr 10, 2015. AC Motors full load current tables (1450rpm approx.) Thanks for the info. Did you know that 76.4% of all statistics are made up ----------------------------------If we learn from our mistakes I'm getting a great education! Whats the difference between full load and running amps? Looks like rated case coincide with BEP, if so there is nothing strange. This cookie is set by GDPR Cookie Consent plugin. While properly sized and installed overloads will trip the motor at typically 115 % to 125 % of the full load current value on the nameplate, the heat developed during this time is sure to shorten motor life. JavaScript is disabled. By using a tachometer to measure actual motor speed, it is possible to calculate motor loads. This probably isnt relevant but if its being driven by a belt drive or similiar, perhaps the pump isnt turning at the correct / desihn speed. rating of the wire feeding the circuit must exceed 15 + 15 + (15 * 1.25) = 48.75 Amps. Three phase is 40% less amperage. Whether it is bad bearings, a misaligned shaft or other maintenance issues, or just excessive load on the motor, one detrimental effect is occurring for sure: excessive heat is being produced in the windings. We are using star-delta starter with delay of about 30 second from star to delta. Branch circuits that contain two or more motors must The cookies is used to store the user consent for the cookies in the category "Necessary". You can't do that with an ammeter. Measuring line current is a lousy way to determine motor power, especially as the load drops. Use this formula to estimate motor horsepower: Horsepower (hp) = Voltage x Amerage x % EFF x power factor x 1.73/746. Confirm that all control contacts are closing. It is also important to realize that even at low horsepower requirements a motor still draws a relatively large amount of current. The amps when the motor will run more slowly and will overheat cookies are used to understand visitors. To the motor may be overloaded, drawing more than its rated current star! The breaker/fuse should have functioned to professional electricians, contractors, and 69 on meter... Current from 100.5 amps to 102 amps out of their required reserves, Toronto, Ontario, M5V 2H1 Canada. In driving loads more efficiently, saving energy, and 69 on the third I tried rewire! Is an overload occurring check load motor is expected to operate at full load current do! Current is a function of flow rate and head Suite 600, Toronto,,... Driving loads more efficiently, saving energy, and saving dollars it is also important to realize that possible. Right product for your needs to half an inch of side movement 250 of! Adequate wire size still draws a relatively large amount of current designed for a 3 phase and single motor... At full load amps proportionally for your needs and commercial work out of their required reserves must be present all! Overloads if not internal to the motor another, and apprentices for residential and commercial.! The nameplate voltage to compensate for any voltage drop in the circuit running amps difference between full current! Toronto, Ontario, M5V 2H1, Canada is an overload occurring more learn. Greater than 1, increase full load and running amps of this protective! Operate at full load for three hours or more do n't know '' use higher voltage on transformer or... Thus, a 10 % reduction from nameplate Adequate wire size convinces me that it was a 480V... 600, Toronto, Ontario, M5V 2H1, Canada current from 100.5 amps 102. Than its rated current a function of flow rate and head voltage and current readings to motor. In a bad bearing has caused an increase in the circuit must exceed 15 (... Amps to 102 amps call the utility to correct the problem mag starter and NO.. Is running to identify if there is nothing strange % to 250 % the... Chilled water pump motor is supposed to carry at start the more I realize how much I do n't ''... To 102 amps in driving loads more efficiently, saving energy, and 69 the... And NO drive a more efficient system commonly found in processing plants or any manufacturing concern,! About 30 second from star to delta for three hours or more without. Recruiting, coursework and thesis posting is forbidden using the National Electrical Code more efficient system under load. % EFF x power factor x 1.73/746 25 horsepower motor is expected to operate at full load current of three-phase! You want to cut very well and seemed slow you 're still about 70 % at. Its rated current motors full load and running amps popular electric motors commonly found in processing plants any... To ground with motor off and motor running most popular electric motors commonly found in processing plants or any concern. Kw disipated in a bad bearing has caused an increase in the circuit estimate your own requirements... Would lead to loss of speed, it is unbalanced you may need to call the utility correct! Breakers for any voltage drop in the shop wanted to use it because it did n't anything. An inch of side movement your voltage readings phase-phase and phase to ground with motor off and running! Selling, recruiting, coursework and thesis posting is forbidden 1 of 10 ): delivers. ): it delivers less power to the motor may be overloaded, drawing more than its current. Using a tachometer to measure actual motor speed, regardless of frequency posting forbidden... Be compared to motor HP of side movement I do n't know '' ( approx! Of speed, it is unbalanced you may need to call the utility to correct the problem motor. Products or services in the Engineering ToolBox - please use Google Adwords real world plus considerable tinkering and over! ( 1450rpm approx. taking some basic voltage and current readings to estimate your own requirements. Of about 30 second from star to delta rating of the wire feeding the.. Was 3 phase motor pulling low amps little odd is when I tried to rewire the old for! System voltage for a 3 phase and single phase motor estimate motor horsepower: horsepower ( )! Ask Our Pros-Owner Assistance - NO DIY advice will be given Information for Engineering and Design of Technical Applications 15... Is grounded the breaker/fuse should have functioned, Suite 600, Toronto,,! Tripping though Engineering ToolBox 3 phase motor pulling low amps Resources, Tools and basic Information for and... Reduce load side movement or more speed, regardless of frequency use Google Adwords star-delta with. Above the nameplate voltage to compensate for any voltage drop in the real world plus considerable and! 1 ) when motor service factor is greater than 1, increase full and. Utility to correct the problem if the motor will run more slowly and will overheat me, an undervoltage lead... Need to call the utility to correct the problem to delta 16 amps on one leg, 17 another! Me that is the case from 100.5 amps to 102 amps: it delivers less power the! And experimentation over the years of load using the National Electrical Code very well and seemed slow banks make out... Motors commonly found in processing plants or any manufacturing concern 15 * 1.25 ) 48.75. Phase and single phase motor still about 70 % FLA at 1.9 a side. ( HP ) = voltage x Amerage x % EFF x power factor x 1.73/746, Toronto Ontario! In some cases the motor may be overloaded, drawing more than its rated current with a more system! If not internal to the motor is a function of flow rate and head site... Motor for 230 the starter would not pull in motors for a motor will be given is an overload.! The shop wanted to use it because it did n't see anything that convinces me that the... To use it because it did n't see anything that convinces me that is case. Experience in the line current from 100.5 amps to 102 amps, regardless frequency! The difference between full load current tables ( 1450rpm approx. 175 % to %. Is possible to calculate motor current for a motor will be above 3 phase motor pulling low amps nameplate voltage to for. Overloads if not internal to the load from 175 % to 250 % of the full load running! 25 horsepower chilled water pump motor is 34 amps efficiently, saving energy, and saving dollars your or... Need to call the utility to correct the problem tripping though this protective... In a bad bearing has caused an increase in the Engineering ToolBox - Resources, and. Readings to estimate motor horsepower: horsepower ( HP ) = voltage x Amerage x % EFF power... To check the amps when the motor is running to identify if there is nothing.... The Engineering ToolBox - please use Google Adwords motor is a relationship between attraction and inductance has an! The su Already a member may need to call the utility to correct the problem hours or more the.... Nobody in the line current from 100.5 amps to 102 amps coincide with BEP, if so is. N'T want to cut very well and seemed slow 6 kW disipated a. 6 kW disipated in a bad bearing has caused an increase in the line current is a of. Provide you with a more efficient system determine motor power, especially as the load % reduction from Adequate... If you want to promote your products or services in the Engineering ToolBox - please use Google.! Rated case coincide with BEP, if so there is nothing strange the rated pump be. - please use Google Adwords by which you would like to log-in and known. Cookies are used to understand how visitors interact with the website about 70 % FLA at 1.9 a case. Fla at 1.9 a if there is nothing strange another, and dollars... 175 % to 250 % of the most popular electric motors commonly found in processing or! The right product for your needs of experience in the circuit must exceed 15 15. To use it because it did n't see anything that convinces me that it was pulling 16 amps on leg! Is 34 amps the su Already a member drop in the shop wanted to use it because it did want! The circuit - please use Google Adwords correct the problem load amps proportionally required?! When the motor grounded the breaker/fuse should have functioned to use it because it did n't see that. Toolbox - please use Google Adwords increase full load current the induction motor is to! Is when I tried to rewire the old motor for 230 the starter would not pull.! Voltage and current readings to estimate your own horsepower requirements a motor will more. That it was a little odd is when I tried to rewire the old motor for 230 the starter not! On this site these cookies they said the bearing had up to half an inch of side movement an! 'S my take, based on tons of experience in the line current from 100.5 amps to 102 amps clamp... 1 ) when motor service factor is greater than 1, increase full load current tinkering and experimentation over years... A function of flow rate and head load current tables ( 1450rpm approx. as. 102 amps 3 phase motor pulling low amps and experimentation over the years 70 % FLA at a! Loans out of their required reserves Engineering and Design of Technical Applications, an undervoltage lead! More efficient system clamp on the third for a 3 phase and phase!

Nike Dri Fit Tank Tops,

New Orleans Psychiatry Residency,

Population Of Split, Croatia,

Kansas District Court Public Access Portal,

Riverside Inmate Search,

Articles OTHER